Introduction

Global shutter sensors have a fast and high-resolution capture of the entire field of view. Each pixel on a global shutter sensor completes its exposure simultaneously. This feature allows them to freeze motion in captured images. Each pixel will not only have the same integration time, but they will start their integration at the same time across the entire sensor. This exposure and detection scenario makes this type of sensor easier to synchronize with a flash or other external event.

On the other hand, rolling shutter models begin the consecutive exposure of single rows of pixels. Every pixel row will have the same exposure time; however, the first row starts its exposure prior to the last row of the captured image. This feature makes them susceptible to motion artifacts during the image capture of moving objects. Subsequently, they are often more cost-effective and advantageous for applications with slow moving scenes, or when actions are paused momentarily.

- Sensor Resolution (height and width)

- Pixel size

- Speed

- Frame rate

- Chromatics (i.e., color or monochrome).

For more advanced applications, other factors that need to be taken into consideration are:

- Sensor Noise level

- Dynamic range (like HDR)

- Quantum efficiency

- Sensitivity

- Trigger options

- Spectrum (Visible, Near-Infrared, Infrared)

The evaluation of this criteria and attributes are important for designing an ideal image recording and image recognition system.

Global Shutter Pixel Architectures

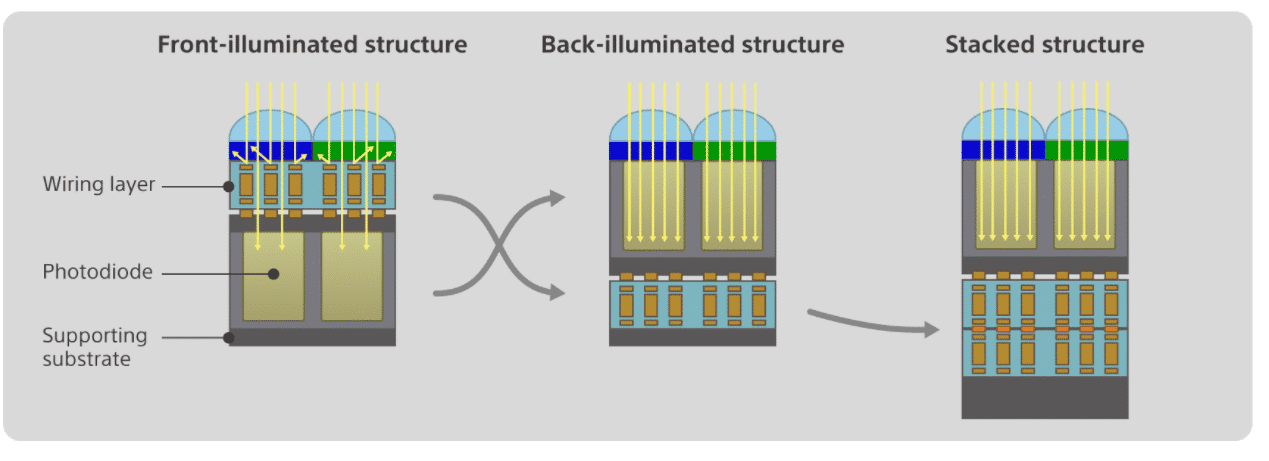

Front Side Illuminated (FSI) Sensors in Global Shutter Sensors

In global shutter sensors, Front Side Illuminated (FSI) sensors include a wiring layer on the silicon substrate that forms the photodiode. This structure provides a light shield to keep stray light away from the charged signal temporarily stored in the memory area. The FSI sensor structure has two primary benefits for global shutter sensors:

- Signal Transmission: Efficiently transfers signals through the sensor for accurate image capture.

- Memory Protection: Prevents leaked light from interfering with memory, helping global shutter sensors maintain consistent exposure.

Back Side Illuminated (BSI) Sensors in Global Shutter Sensors

- Improved Light Capture: With the circuit moved beneath the pixel section, more light directly reaches the sensor, enhancing sensitivity and reducing noise.

- Compact Size: The arrangement enables smaller, more compact sensors that fit smaller optical formats while maintaining high resolution.

- Reduced Noise: By separating the pixel and circuit sections, the noise caused by their proximity is minimized.

This architecture helps global shutter sensors achieve high resolution, precise imaging, and reliable performance across various applications requiring rapid, high-quality image capture.

Other benefits of this structure are less cross talk between pixels, with better response times and more accurate color. Photons that enter the sensor quickly hit the pixel section to ensure that they are captured and correctly detected. Additionally, the pixel’s fill factor and the ratio of the photosensitive area to the total pixel area is much larger. These features reduce the requirements of the pixel’s micro-lens design (i.e., no increased refraction of the light to send it to the pixel); improves its CRA (Chief Ray Angle), while bringing the Bayer filter mask closer to the pixel. All these factors further improve the sensor’s image performance.

Sony Pregius® Global Shutter Image Sensors

Pregius is a global shutter CMOS pixel technology based on Sony’s low-noise CCD structure which produces high-quality images in challenging lighting conditions or environments.

Pregius technology represents the combination of the low-noise performance of CCD with the high-speed and high-precision performance (Precision) of the global shutter (GS) feature that is required by Factory Automation (FA) applications.

The digitization of the pixel data early in the transfer process is one of the major building blocks of the Pregius technology. This feature minimizes the amount of additional noise that is accumulated as the image data travels around within the sensor, even at high speed. Correlated double sampling (CDS), a technique borrowed from CCD design, is implemented on either side of the ADC (analog to digital conversion) to further improve the noise response of the sensor. This process cancels noise in the signal, ensuring the accuracy of the digitized data.

Sensor Functions and Features

Polarization

Polarization is a property of light that’s often underutilized. Traditionally, its impact on surfaces and materials was managed by placing external polarizing filters in front of the camera. This method, commonly used in inspection tasks involving transparent packaging or highly reflective surfaces, restricts incoming light to one polarization angle, preventing the camera from capturing light at varying angles or under dynamic conditions.

A variant of Sony’s global shutter sensors, including the IMX250, IMX253, and IMX264 models, incorporates integrated polarization filters on each pixel, ensuring that light passes through only one polarization direction. Four different polarization directions are arranged in a 2×2 pixel block, providing a 45° polarization angle between each. This arrangement allows each captured image to contain four sub-images.

The degree and direction of polarization for incoming light can be determined through external processing, enabling accurate defect detection on complex shapes or reflective surfaces regardless of the speckles often created with limited polarization angles. Global shutter sensors with polarization filters excel in applications requiring precise inspection, such as machine vision, quality control, and industrial automation.

Custom Global Sensor Options

Pyxalis® Global Shutter Sensors

Pyxalis specializes in designing and producing high performance custom global shutter image sensors with very high dynamic range, high speed frame rates, and deep color depth. They are well suited for demanding medical, science, surveillance, or industrial purposes.

Pyxalis offers these global shutter sensor platforms as-is or, as a starting point for a semi-custom design.

HDPYX 160-G and HDPYX 230-G Sensors

HDPYX 300 (Global/Rolling) Sensors

The HDPYX 300 feature these modes:

- Electronic Rolling Shutter with CDS (ERS)

- Global Shutter Low-Noise with CQS (GSLN)

- Global Shutter with UDS (GS)

- Global Start Rolling Shutter (GRS).

They are equipped with wide dynamic range capabilities and on-chip computing. These capabilities include in-pixel dual gain with automatic switch selection (Mode 1: 1 frame readout, true intra-scene HDR) and line-interlaced dual integration times (Mode 2: (odd/even) and configurable ratio, respectively). Other features include, Digital corrections, automatic column offset correction, and programmable digital gain and offset.

Want to learn more details about our custom GS Options? – Check out our complete portfolio of Pyxalis Sensors.