3D cameras for industrial applications have to operate in harsh production environments and reliably detect moving objects at speed, e.g. when the camera is mounted on a robot arm. Stable and latency-free data transmission over extended distances is essential – using GigE Vision, for example – as is straightforward integration. FRAMOS – a global partner for vision technologies – has developed an industrial version of the Intel® RealSense™ camera that offers gigabit Ethernet connectivity and an IP66-rated dustproof and water-resistant enclosure. So now there is an easy way to integrate 3D vision into harsh environments. The plug-and-play solution enables real-time positioning, orientation and tracking for robots, navigation for automated guided vehicles (AGVs), and many other “smart” machines, e.g. in medical engineering.

In recent years, industrial image processing (machine vision) has secured a permanent place in automation, especially in established fields such as production and quality control. Now the next step is 3D vision, a technology that has the potential to change entire industries. The future will belong to intelligent, “seeing” devices. Robotics, automated guided vehicles (AGVs) and medical devices can benefit from the new machine vision solutions, especially with the arrival of industrial camera systems that can reliably detect even fast-moving objects in harsh environments. Their real-time depth data provides the basis for fully automated processes in production lines, logistics, and industrial applications where intelligent devices make autonomous decisions.

Depth cameras began their rise to prominence in the consumer sector, and are now making inroads into industrial environments. This “career path” has certainly brought advantages: large volumes mean prices are affordable, for example, while short product life cycles and development cycles have allowed the technology to make rapid progress. “Off-the-shelf” technology makes handling easier, too. Significantly, this also speeds up the whole vision development process. RealSense™ cameras from Intel® are a technologically advanced yet relatively inexpensive example of this technology.

Fit for industrial use

Industrial automation has different requirements than the consumer segment. 3D cameras for industrial use have to operate in harsh production environments and reliably detect moving objects at speed, e.g. when the camera is mounted on a robot arm. Stable and latency-free data transmission over extended distances is essential – using GigE Vision, for example – as is straightforward integration. With its D435e 3D camera (see fig. 1), FRAMOS – a global partner for vision technologies – has set standards in this field that will accelerate the development of innovative vision applications in a wide range of industries.

The industrial version of the Intel® RealSense™ camera offers gigabit Ethernet connectivity and a sturdy IP66-rated dustproof and water-resistant aluminium housing. It operates reliably at ambient temperatures between 0 and 55 °C, and is ideally equipped in other ways too for use in harsh production conditions. The screw-fastening gigabit Ethernet (M12) and power supply (M8, for 12 or 24 V) connections can withstand movement and vibration, unlike USB cables. If it is necessary to work without separate power cables, a version with Power over Ethernet (PoE) is available. Four M3 mounting holes on the body make for easier installation, e.g. fastening in robotics applications. Long transmission distances are no problem, either. Image data is preprocessed in the camera and can be sent over cables up to 100 m in length.

Performance in a compact package

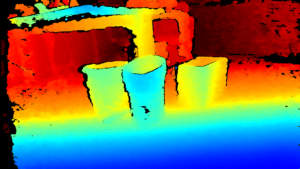

The powerful technology is well protected inside the highly compact camera, which measures 100 x 47 x 38 mm and weighs just 250 g. Its main task is to see in stereo – just like humans do. Viewing objects and things with two eyes produces true, quantified depth perception (see fig. 2). To achieve this, the camera is equipped with the Intel® D430 Depth Module (0.9 MP resolution), the Intel® D4 Vision Processor for depth calculation, and an additional RGB camera module (2 MP resolution).

The camera can be used with the Intel® RealSense™ SDK 2.0 and any other GigE Vision software. Its ease of operation, uncomplicated integration as a plug-and-play 3D vision solution, and affordable price make the robust camera suitable for numerous applications, as more and more industries today demand innovative 3D vision solutions.

Potential applications in all kinds of industries

There are interesting possibilities for the industrial depth camera in robotics. A “seeing” robot can recognise different parts in pick-and-place applications, for example, and set them down accordingly – on a processing station, conveyor, or driverless transport system (see fig. 3). 3D vision gives these driverless systems fully autonomous mobility, enabling them to move around in complete safety and avoid people or other systems without additional installations such as rails or markers. Another application is in medical engineering, where devices with camera systems can automatically ensure and maintain optimal alignment with the patient (see fig. 4).

Collaborative robotics is another field that is benefiting from innovative 3D vision solutions. “Seeing” cobots are much better at interacting with people, which means they can do more and be deployed more flexibly. Gesture control is a promising area of research in this context, and even the retail sector can benefit from 3D vision. If retailers can see how their customers move about in-store, or when and where they stand still, that already tells them a lot. Intelligent retail analytics tools can then supply more insightful findings. The user’s imagination is practically the only limit on the innovative possibilities that 3D vision opens up, and there is an exciting journey ahead.

About the Author

As Product Manager Ferdinand Reitze is responsible for FRAMOS 3D products. Working closely with customers and partners, observing the market, and identifying trends, his job is to translate all this into a sound strategy for depth sensing, always keeping the customer’s requirements at the center. During the process, he draws on his experience in sales and strategic business development as well as his curiosity for new technologies.